Product Description

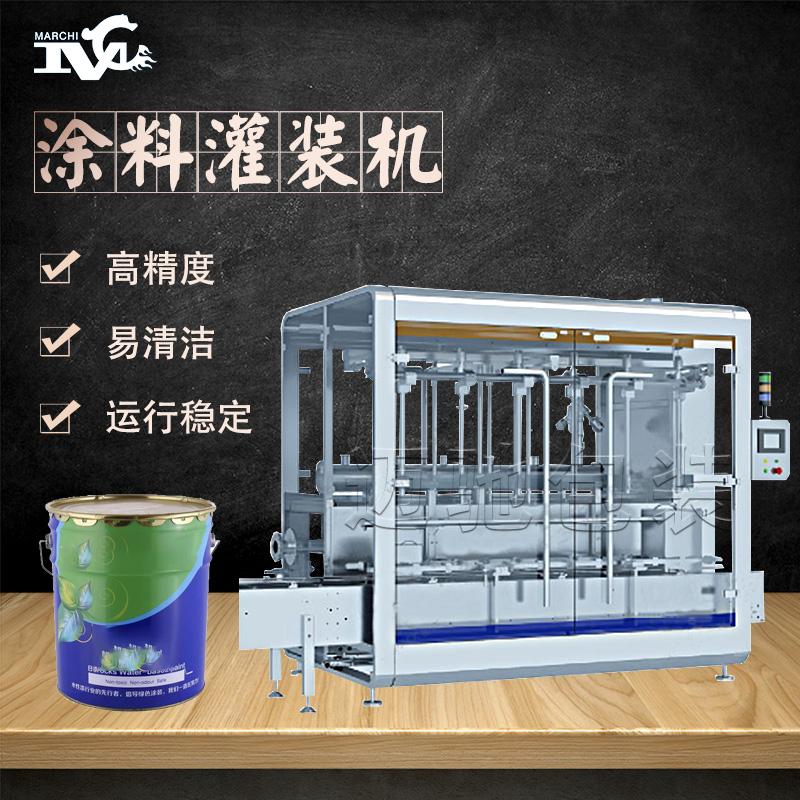

Coating filling machine, automatic quantitative coating filling machine, automatic coating filling machine

Scope of application:

Food: edible oil, blending oil, sunflower oil, corn oil, soybean oil, peanut oil, olive oil, camellia oil, rape oil, walnut oil, rice oil, etc

Daily chemical: lubricating oil, paint, latex paint, putty paste, waterproof coating, diatom mud

Equipment features:

1. The machine adopts programmable logic controller (PLC), high-speed industrial control configuration software for real-time monitoring control, easy to use and adjust.

2. Each filling head has a weighing and feedback system, which can set the filling amount of each head and make a single micro-adjustment.

3. Photoelectric sensor, proximity switch, etc. are advanced sensing elements, so that no bucket no filling, blocking the bucket will automatically stop and alarm.

4. The filling method is subducted, which can effectively reduce the generation of foam, and can meet the filling of materials with different characteristics.

5. The machine is made according to GMP standard, and the pipes are connected by quick assembly, easy to disassemble and clean. The parts in contact with materials and exposed parts are made of stainless steel. Environmental protection, beautiful, can adapt to a variety of different environment work.

Equipment parameters:

Model McYt-cz-2t McYt-cz-4t McYt-cz-6t McYt-cz-8t

Head count 2, 4, 6, 8

Applicable bottle type (mm) L:160 ~ 360, W:100 ~ 300, H:250 ~ 500, φ :≥40

Production capacity 30kg:240 bottles/hour 30kg:450 bottles/hour 30kg:520 bottles/hour 30kg:600 bottles/hour

Filling range (g) ≤±0.3 ≤±0.3 ≤±0.3 ≤±0.3 ≤±0.3

Dimensions L x W x H(mm) 1500 x 1700 x 2300 3500 x 1700 x 2300 2500 x 1700 x 2300 4500 x 1700 x 2300

AC220v power supply; 50 hz 2 kw AC220v; 50 hz 2 kw AC220v; 50 hz 2 kw AC220v; 50 hz 2.5 kw

Specifications︰

Model McYt-cz-2t McYt-cz-4t McYt-cz-6t McYt-cz-8t

Head count 2, 4, 6, 8

Applicable bottle type (mm) L:160 ~ 360, W:100 ~ 300, H:250 ~ 500, φ :≥40

Production capacity 30kg:240 bottles/hour 30kg:450 bottles/hour 30kg:520 bottles/hour 30kg:600 bottles/hour

Filling range (g) ≤±0.3 ≤±0.3 ≤±0.3 ≤±0.3 ≤±0.3

Dimensions L x W x H(mm) 1500 x 1700 x 2300 3500 x 1700 x 2300 2500 x 1700 x 2300 4500 x 1700 x 2300

AC220v power supply; 50 hz 2 kw AC220v; 50 hz 2 kw AC220v; 50 hz 2 kw AC220v; 50 hz 2.5 kw

Advantages︰

1. The machine adopts programmable logic controller (PLC), high-speed industrial control configuration software for real-time monitoring control, easy to use and adjust.

2. Each filling head has a weighing and feedback system, which can set the filling amount of each head and make a single micro-adjustment.

3. Photoelectric sensor, proximity switch, etc. are advanced sensing elements, so that no bucket no filling, blocking the bucket will automatically stop and alarm.

4. The filling method is subducted, which can effectively reduce the generation of foam, and can meet the filling of materials with different characteristics.

5. The machine is made according to GMP standard, and the pipes are connected by quick assembly, easy to disassemble and clean. The parts in contact with materials and exposed parts are made of stainless steel. Environmental protection, beautiful, can adapt to a variety of different environment work.

Scope of application ︰

Food: edible oil, blending oil, sunflower oil, corn oil, soybean oil, peanut oil, olive oil, camellia oil, rape oil, walnut oil, rice oil, etc

Daily chemical: lubricating oil, paint, latex paint, putty paste, waterproof coating, diatom mud

Suitable Range︰

Food: edible oil, blending oil, sunflower oil, corn oil, soybean oil, peanut oil, olive oil, camellia oil, rape oil, walnut oil, rice oil, etc

Daily chemical: lubricating oil, paint, latex paint, putty paste, waterproof coating, diatom mud

Custom Field︰

Coating filling machine, automatic quantitative coating filling machine, automatic coating filling machine

Custom Field︰

Coating filling machine, automatic quantitative coating filling machine, automatic coating filling machine